Indoor Positioning with Ultra-wideband

Indoor tracking in industrial environments often requires very precise localization. For this purpose we offer solutions based on the short-range radio technology Ultra-wideband (UWB). It does not work with consumer standards such as Wi-Fi and Bluetooth Low Energy, but offers an accuracy better than 30 cm.

Indoor positioning with Ultra-wideband has some significant advantages: The accuracy is 10-30 cm, which is considerably better than when working with beacons (1-3 meters) or Wi-Fi (5-15 meters). Latency time is very low (position request up to 100 times/second). Height differences can be measured accurately. However, the technique is a special solution which requires appropriate components and thus is mostly suitable for special industry applications.

Functionality of Indoor Localization with Ultra-wideband

Ultra-wideband is a short-range radio technology which can be used for indoor positioning. In contrast to Bluetooth Low Energy and Wi-Fi, positioning is done with transit time methodology (Time of Flight, ToF) instead of the measurement of signal strengths (Receive Signal Strength Indicator, RSSI). This method measures the running time of light between an object and several receivers (anchors – infsoft Locator Nodes). For the exact localization of an object at least 3 receivers are necessary (trilateration). Also, there must be direct line-of-sight between receiver and transmitter.

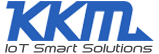

Setting up an UWB-Based System: Two ApproachesSERVER-BASED

In order to localize assets, the infsoft Locator Tag measures the distance to several infsoft Locator Nodes and sends the data back to them. infsoft Locator Nodes are modularly structured and have an integrated UWB module, which lets them act as a receiver. The infsoft Locator Node processes the data it receives and sends them to the KKM platform via Wi-Fi, Ethernet or UMTS. Here, the position is displayed for example on a map.

SERVER-BASED

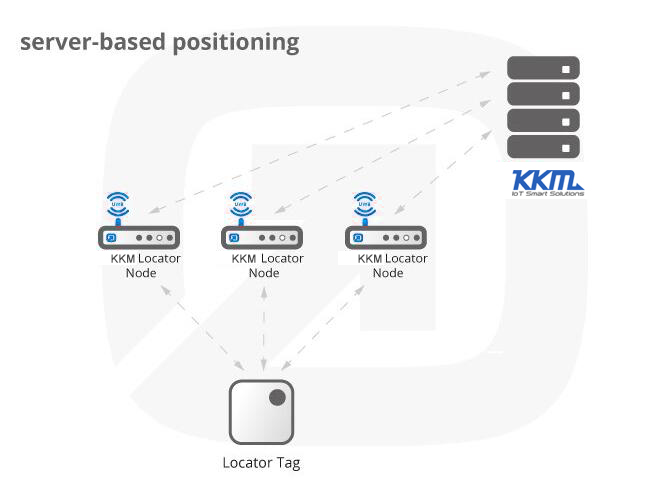

If the positioning data should be immediately displayed on a mobile device (smartphone), the infsoft Locator Tags can communicate with the smartphone via Bluetooth or USB interface directly. Time of Flight is measured, just like explained above, but the Locator Tag exchanges the data with the device via Bluetooth or USB port. The data can be sent to the KKM platform from the device, if necessary.

Technical Features of Ultra-wideband

- Usage of extremely wide frequency bands with a bandwidth of at least 500 MHz

- Almost no interferences

- Frequency bandwidth 3,1 – 10,6 GHz

- Transmission power 0,5 mW / −41,3 dBm/MHz

- Reach 10 – 150 m (depends on the use case)

- Data rate 110 kbit/s – 6.8 mbit/s

Use Cases for Locating Systems Using Ultra-wideband

Indoor/outdoor positioning with Ultra-wideband can be used in various application scenarios. Here are some examples:

In a warehouse or production facility, work equipment such as forklifts can be tracked with high precision. The vehicles’ orientation (viewing direction) can also be adjusted, for example in poor visibility conditions.

Software solution used: Indoor Tracking

Sensors used: Ultra-wideband

Examples of use: Tracking of Floor Conveyors and Goods in Logistics, Indoor Navigation and Tracking of Tugger Trains

The analysis of routes – i.e. in a production facility – can help in optimizing paths and processes and can provide key figures for decisions.

Software solution used: Indoor Tracking

Sensors used: Ultra-wideband

Example of use: Process Optimization in Automotive Manufacturing

Assets in extensive warehouse systems (such as pallets) can be recorded and their location, service life and movement history can be retrieved. With asset tracking, it is possible to prevent wrong deliveries or incorrect inventories.

Software solution used: Indoor Tracking

Sensors used: Ultra-wideband

Example of use: Indoor Tracking of Tool Boxes in the Hangar

Punctual production supply in production industries can be facilitated by applying a tracking system for tugger trains and a machine learning system.

Software solution used: Indoor Tracking, Geo-Based Services, Machine Learning

Sensors used: Ultra-wideband

Example of use: Management of Tugger Trains in Industrial Production